Savings Far Beyond The Washpad

Improving Safety And Reducing Cost

The Cost of a Safe Washpad: What It Really Takes

When a refinery enters turnaround mode, the pace ramps up - and so does the risk. The washpad becomes a pressure point where safety, compliance, and operational continuity all collide. Ensuring it runs safely isn’t optional - it’s strategic risk management. Here’s how a Tech Sonic Washpad can improve safety while reducing costs:

Engineering-Grade Infrastructure: Temporary setups won’t cut it (or shouldn't). Safe operation demands certified wash bays, proper wastewater management, a safe, hazard-free and slip-resistant workspace, with good access controls and adequate lighting - all designed and built to withstand heavy-duty, high-volume use. With a Tech Sonic Washpad Lease, the capex is ours, and your lease expense is dwarfed by the cost of a single serious injury or environmental violation.

Trained Personnel: A safe washpad needs more than general labor. You need workers trained in ultra-high pressure equipment operation, asset handling, and emergency response. Investing in that level of preparedness saves you from reactive firefighting—literally and figuratively.

Regulatory Compliance: Turnarounds trigger intense scrutiny from environmental and safety regulators. Proper permitting, wastewater handling, air monitoring, and hazardous material containment all require upfront planning—and expert oversight. One missed detail could delay restart or trigger fines.

Downtime Prevention: Every incident on the washpad—whether it’s a spill, slip, or equipment failure—can cause ripple effects across the entire turnaround schedule. That’s lost production, delayed restart, and potential contract penalties. The “cost” of safety? Far less than the cost of avoidable downtime.

Operational Resilience: Emergency shutoff valves, spill containment kits, proper signage, and wash water recycling systems all cost money—but they also buy you control. And during a turnaround, control is everything.

Bottom line: Safe washpad operation isn’t a line item—it’s an insurance policy against regulatory headaches, injuries, and costly delays. In turnaround mode, every hour counts. Investing in washpad safety protects the timeline, the team, and the bottom line.

Reducing Equipment Damage

Wipe-out Washpad Wreckage

On a traditional hydroblasting washpad, where heavy exchangers swing from cranes in the crowded, high pressure, high stress environment, accidents are not uncommon.

At Tech Sonic, we're tackling the problem of equipment damage in a big way. We’ve engineered a washpad system that not only protects your personnel, but also safeguards your valuable equipment - from start to finish.

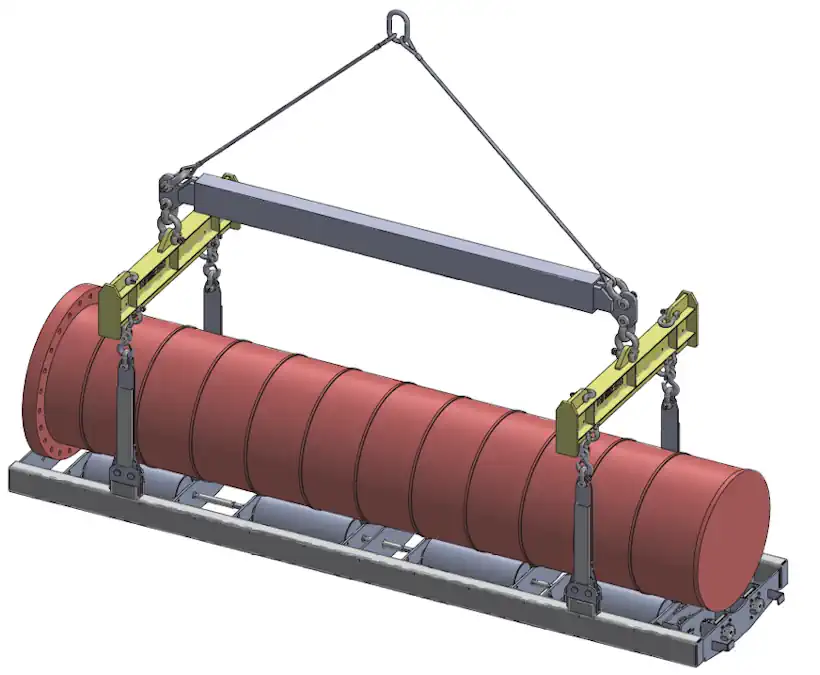

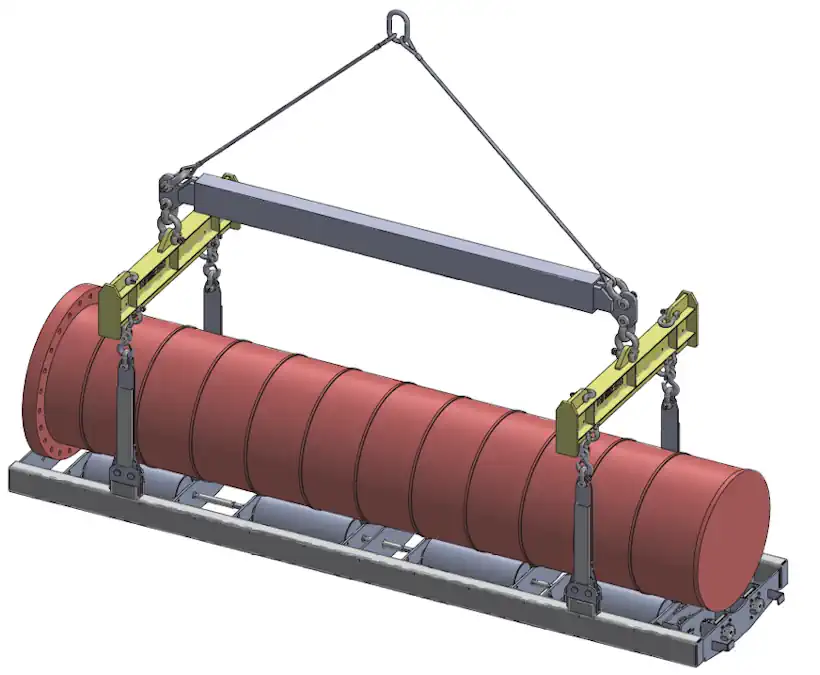

The biggest dangers stem from crane-and-sling transfers and hydraulic rollers - bundles can slip, collide with other heavy gear, or topple off entirely. Our unique bundle cradles and dual transit gantry crane solve this problem. Once a bundle is placed in its cradle, it stays put until cleaning is done - no slings, no risk, and no dedicated crane or riggers needed. Large-diameter, widely spaced rollers add another layer of safety and accuracy, allowing each exchanger to be precisely positioned for ultrasonic, shell-side, and tube-side rinsing.

On top of that, we reduce hydroblasting by 75%, and our automated hydroblasting with computerized pumps drastically lowers the chance of tube damage. Ultrasonic cleaning loosens deposits inside and around the tubes, sometimes eliminating the need for ID blasting altogether. Robots handle the hydroblasting flawlessly - no fatigue, stress, or human error - ensuring every tube is cleaned without risk of blowouts or missed spots.

Tech Sonic’s smart washpad technology slashes downtime, protects your equipment, and keeps your team safe - saving you time, money, and headaches compared to any traditional washpad setup.

The Cost of a Safe Washpad: What It Really Takes

When a refinery enters turnaround mode, the pace ramps up - and so does the risk. The washpad becomes a pressure point where safety, compliance, and operational continuity all collide. Ensuring it runs safely isn’t optional - it’s strategic risk management. Here’s how a Tech Sonic Washpad can improve safety while reducing costs:

Engineering-Grade Infrastructure: Temporary setups won’t cut it (or shouldn't). Safe operation demands certified wash bays, proper wastewater management, a safe, hazard-free and slip-resistant workspace, with good access controls and adequate lighting - all designed and built to withstand heavy-duty, high-volume use. With a Tech Sonic Washpad Lease, the capex is ours, and your lease expense is dwarfed by the cost of a single serious injury or environmental violation.

Trained Personnel: A safe washpad needs more than general labor. You need workers trained in ultra-high pressure equipment operation, asset handling, and emergency response. Investing in that level of preparedness saves you from reactive firefighting—literally and figuratively.

Regulatory Compliance: Turnarounds trigger intense scrutiny from environmental and safety regulators. Proper permitting, wastewater handling, air monitoring, and hazardous material containment all require upfront planning—and expert oversight. One missed detail could delay restart or trigger fines.

Downtime Prevention: Every incident on the washpad—whether it’s a spill, slip, or equipment failure—can cause ripple effects across the entire turnaround schedule. That’s lost production, delayed restart, and potential contract penalties. The “cost” of safety? Far less than the cost of avoidable downtime.

Operational Resilience: Emergency shutoff valves, spill containment kits, proper signage, and wash water recycling systems all cost money—but they also buy you control. And during a turnaround, control is everything.

Bottom line: Safe washpad operation isn’t a line item—it’s an insurance policy against regulatory headaches, injuries, and costly delays. In turnaround mode, every hour counts. Investing in washpad safety protects the timeline, the team, and the bottom line.

Wipe-out Washpad Wreckage

On a traditional hydroblasting washpad, where heavy exchangers swing from cranes in the crowded, high pressure, high stress environment, accidents are not uncommon.

At Tech Sonic, we're tackling the problem of equipment damage in a big way. We’ve engineered a washpad system that not only protects your personnel, but also safeguards your valuable equipment - from start to finish.

The biggest dangers stem from crane-and-sling transfers and hydraulic rollers - bundles can slip, collide with other heavy gear, or topple off entirely. Our unique bundle cradles and dual transit gantry crane solve this problem. Once a bundle is placed in its cradle, it stays put until cleaning is done - no slings, no risk, and no dedicated crane or riggers needed. Large-diameter, widely spaced rollers add another layer of safety and accuracy, allowing each exchanger to be precisely positioned for ultrasonic, shell-side, and tube-side rinsing.

On top of that, we reduce hydroblasting by 75%, and our automated hydroblasting with computerized pumps drastically lowers the chance of tube damage. Ultrasonic cleaning loosens deposits inside and around the tubes, sometimes eliminating the need for ID blasting altogether. Robots handle the hydroblasting flawlessly - no fatigue, stress, or human error - ensuring every tube is cleaned without risk of blowouts or missed spots.

Tech Sonic’s smart washpad technology slashes downtime, protects your equipment, and keeps your team safe - saving you time, money, and headaches compared to any traditional washpad setup.